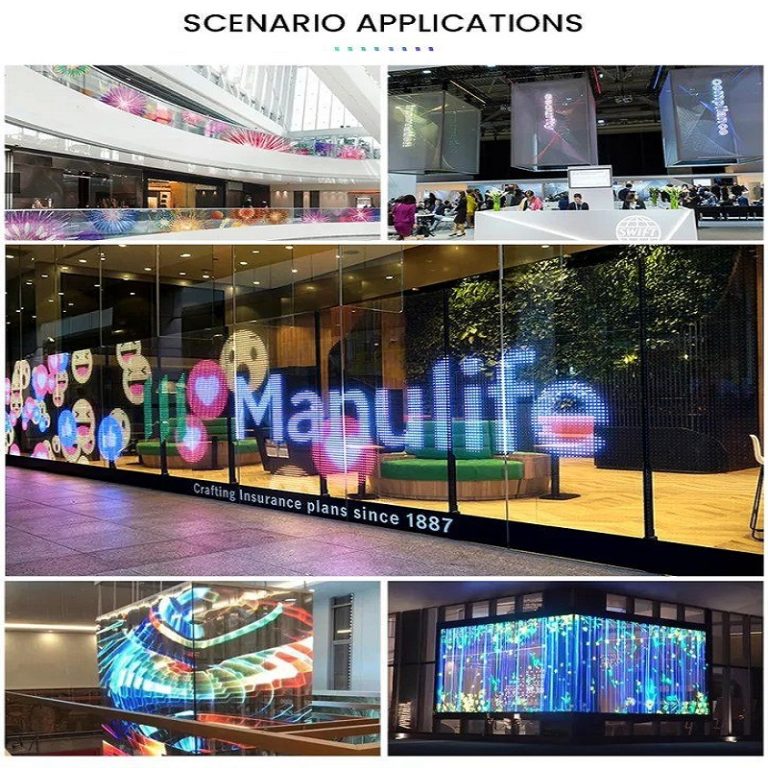

LED Electronic Screen | High Definition Display Solutions to Light Up Your Every Moment

2025 Survival Guide: Outdoor LED Screens’ Compliance & Extreme Weather Fit

2025 has found the Outdoor LED Screens industry grappling with two distinct sets of constraints. On one side are policies created to regulate light pollution, which have set parameters for screen brightness and installation specifications, while frequent extreme weather events have increased the maintenance costs of unsuitable screens significantly. Under such pressure from both policy regulation and natural environment forces, “light pollution compliance” and “extreme weather adaptability” have moved beyond being optional features to become core competitive advantages that help companies seize market opportunities.

Light Pollution Compliance: Methods and Strategies for Overcoming Policy Red Lines

Light pollution control requires striking a balance between display effects and environmental compatibility, and creating a comprehensive solution from three aspects: technology upgrades, compliance planning, and intelligent management.

1. Technical Aspects: Optimization + Intelligent Dimming

On the hardware side, low-glare technology is utilized, which reduces screen reflectivity through optical processing to minimize interference from direct light sources. Optimized light source characteristics help regulate color temperature and spectral composition as well as color temperature balance for visual comfort while remaining eco-friendly; additionally, a transparent structural design may also be adopted to lower light output intensity without impacting display quality.

Intelligent dimming systems have become an industry standard, using high-precision sensors to track real-time changes in ambient illuminance and adjust for them in real time through multi-level adaptive brightness adjustment, creating a dynamic balance between daytime visibility and nighttime compliance. Advanced solutions may even include predictive algorithms capable of anticipating future illumination levels based on multidimensional data such as time of day and environment, mitigating any risk of exceeding standards at their source.

2. Compliance Aspects: Accommodating Regional Differences + Enhancing Processes

Different regions have differing policy standards, necessitating companies to implement a dynamic policy tracking mechanism capable of matching control requirements across regions. When selecting sites based on regional policy attributes and scenario characteristics for project planning purposes, companies should scientifically select sites according to regulatory departments’ filing and approval processes and avoid sensitive areas that pose compliance risks.

Procedure-wise, new projects should conduct a light pollution assessment before their construction phase, submit an extensive monitoring data report during the completion and acceptance phase, connect to relevant management platforms as required, and establish long-term feedback mechanisms so as to respond swiftly and ensure continuous compliance during operation.

Adaptability in Extreme Climates: Establishing a Reliable Defense Line against Any Environment

Outdoor LED screens are exposed to extremes in climate conditions for long periods. Extreme temperatures, precipitation, wind, sandstorms, salt spray exposure, and other environmental elements may negatively impact their operational stability, necessitating protection upgrades and structural optimization to increase adaptability to any and every scenario.

1. Protection Level and Hardware Configuration

High protection standards have become standard practice, with mainstream products typically meeting IP65 or higher protection standards as an absolute minimum requirement. High-end projects may further upgrade this protection level with comprehensive waterproofing, moisture resistance, salt spray resistance, and UV resistance features. Flame-retardant materials coupled with superior core components improve product durability and environmental adaptability from its inception.

Customized designs are tailored to different climate characteristics to maximize wide temperature operating capabilities and ensure reliable start-up and operation, even in extreme high and low temperature environments. In special environmental areas, anti-corrosion and dustproof structural design is tailored specifically to protect equipment against erosion under harsh conditions.

2. Heat Dissipation and Structural Innovation

Heat dissipation efficiency has an immediate impact on screen longevity and stability, so optimizing cabinet structures with high-efficiency heat dissipation materials, such as active cooling modules, can ensure optimal heat dissipation efficiency while controlling energy consumption levels for better performance degradation and failure risks due to high temperatures. At the same time, low voltage power supplies with energy-saving chip technology help minimize heat generation while simultaneously cutting down power consumption costs.

The modular approach used for structural design facilitates installation, maintenance and component replacement as well as reduced wear rates in complex environments. An optimized installation structure and angle reduce environmental influences directly impacting the screen while at the same time decreasing light leakage into surrounding environments.

Imperative for Success in 2025: Implementation of Compliance and Adaptation Synergistically

Light pollution compliance and climate adaptation do not need to be separate issues; rather, they need to work in harmony in order to ensure long-term sustainable operation.

Priority should be given in product selection to technical solutions that combine energy efficiency with high reliability. Through core technology iterations, power consumption should be decreased while stability is improved – meeting compliance requirements while simultaneously lowering total lifecycle operating costs.

At an operational level, implement a full lifecycle management mechanism featuring regular monitoring + dynamic optimization: regularly calibrating brightness, color temperature and other parameters as part of regular monitoring activities; conducting comprehensive equipment status tests to anticipate any risks in advance through environmental and operational data integration; and reserving suitable spare parts and contingency plans as necessary – with full integration between compliance management with environmental adaptation to create both commercial and social value.

Compliance capabilities will dictate market entry for 2025’s outdoor LED screen market, while climate adaptability determines operational lifespan. Only by employing light pollution control technologies, regional policy adaptation, and extreme environment protection measures can companies establish themselves in what has become an increasingly regulated and complex marketplace, ultimately realizing sustainable development and realizing sustainable development goals.

Supplier of Outdoor LED Screens

Shenzhen Zhongxian Beixin Technology Co., Ltd. is a high-tech company that is located in Shenzhen, Guangdong Province, specializing in the research and development, production, marketing, and professional services of LED application products and providing various LED display integrated solutions for control rooms, commercial advertising, architectural industries, stadiums, churches, and many other applications.

If you need a high-quality LED display, please feel free to contact us. You can click on the product to contact us. (https://www.leyardleddisplay.com/contact-us/)

Exhibition Hall of Made-in-China.com: https://zxbx371.en.made-in-china.com/